Prefabrication is a time-saving technique that reduces the mess. Rather than constructing everything at the building site, countless components are produced in a factory. This is where Keyi comes in. We concentrate on producing 'off the shelf' items of high quality that can be delivered to site pre-finished. That way there’s less waste left once the job is complete. The pieces all fit together very nicely, so there isn’t a lot of extra material you’ll be throwing away. It’s not only good for the environment, but it also saves time and money.

How Prefabrication Can Reduce Construction Waste on Wholesale Projects

When it comes to large-scale projects, prefab container house is a true game changer. Consider, for instance, constructing an apartment house. One downside is that if every wall and floor must be constructed on-site, builders run the risk of cutting too much or else being left with pieces they can’t use again. This can make a lot of waste. But with prefab, Keyi will be able to make these walls and floors in a factory where everything fits just so. And that’s because when those pieces arrive at the site, they fit together like puzzle pieces, leaving almost no waste.

In wholesale projects, for instance, many of the pieces are identical, as in the construction of houses. Rather than each piece being built from the ground up on-site, prefabrication enables mass production. This has the effect of reducing mistakes as well as excess materials. For example, if 100 walls are made at a time, the factory could re-purpose excess materials from one wall to build another. This is a smart use of resources.

And the less time spent on-site, the better for whatever left of construction’s neighborhood. Neighbors won’t mind that there’s not much noise or mess for a while at least. Whether it’s Keyi Prefabricated Solutions, the quicker way to complete your project neatly. When the work is done, the environment comes away better cared for and there’s less mess to clean up. Everyone wins.

Adopting Sustainable Construction Practices - What to Look for In Prefab Solutions

Selecting the right prefabricated offerings is crucial in aiding building projects that are more sustainable. The first thing you’ll want to take into consideration is the materials. Keyi provides environmentally-friendly options, whose sources are renewable or recycled. When developers choose these products, they contribute to helping save the planet as well.

Next, consider the design. Thoughtful design can help prevent waste. Keyi’s team can advise clients on designing with eco-friendly materials and include a limited number of leftover remnants. You might also want to consider the portability of the pieces. If they can be transported without damage, it also cuts waste during shipping.

Finally, consider the effects over time. Are the prefab parts well made? Long-lasting materials are less likely to require repairs or a replacement somewhere down the road. Opting for solutions by Keyi is an intelligent way to craft something that will endure.

Conclusion: Prefabrication is one of the most efficient methods to reduce waste in construction. Builders can construct something beautiful and strong while protecting islands with Keyi’s help. By carefully considering materials, designs and durability, construction can be more sustainable and efficient.

The Best Places to Shop for Quality Prefabricated Products That Reduce Waste

If you’re trying to create something new, be it a house or a school, prefab is the way to go. Prefabrication is when the parts of a building are manufactured offsite in a factory. They’re assembled with care, which ensures they fit together just right. Keyi is a firm that provides good quality prefabricated products to help you build better and throw less. As you search for prefabricated products look for a company like Keyi that works hard at what they do. To find these products, attend construction fairs and do online research. There are a lot of websites where you can see prefabricated items on display, and in many cases read comments about them from others who have used them.

When you pick prefab items from a trustworthy company, you’re doing your part to cut down on waste. This is due to the fact that such items are produced in a production environment where factories can accurately measure and have time to handle materials. They can also recycle unused materials more effectively than construction sites. For instance, if a factory has extra wood or metal on hand, it can use that material to make more parts. Prefabricated products yield fewer scraps on the construction site, which means less trash to manage. If all the products we use in our kitchens fit together Keyi believes, fewer mistakes are made. This allows builders to complete their projects more easily without having to discard excess parts. If you wish to care for the environment and reduce waste, buying prefabricated goods from respectable companies such as Keyi is a wonderful place to begin.

How Prefabricated Elements Can Trim Construction Site Waste

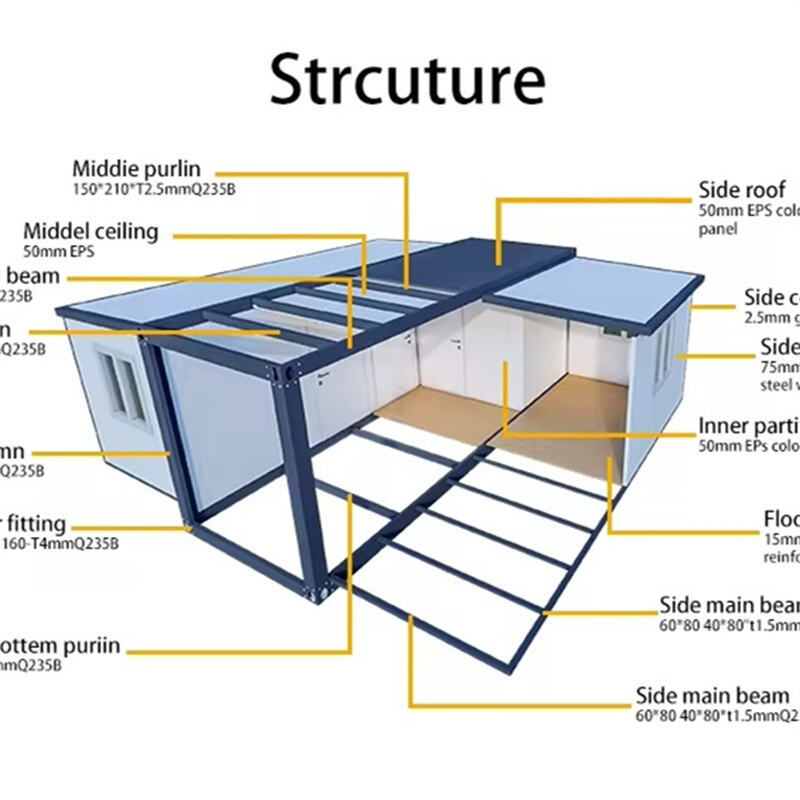

Prefabricated building parts are unique elements produced in an off-site factory. These might be walls, roofs or even floors. This means that, when these parts are delivered to the building site, they can be immediately assembled. This reduces waste in many ways. First, they can be measured and cut in a factory with great precision. That means less opportunity to make the types of errors that would produce extra trash. So, for instance, if someone takes a piece of wood and they cut it too short, then that piece may not be useful at all anymore. But if the wood is fabricated in a factory, workers there can ensure it’s the right size before it ever leaves the factory.

It also saves time working from the prefabricated units. Construction managers who had originally been trained as builders working with ordinary materials typically had to cut and shape those materials on-site. The result, though, can be lots of leftover “waste” pieces that you then discard. When you use prefabricated components, everything is already formed and it is click-click-ready-to-go. That’s less to cut and shape, less waste. Keyi specializes in prefabricated components that can be smoothly assembled. 112, this minimizes the amount of additional material required on site, and waste in general. And when builders use prefabricated parts, they are able to build more quickly and with an improved environmental impact. This benefits the environment as less trash is generated, while also saving taxpayers money. The less waste, the less it costs to dispose of and the more efficiently materials can be used.

How Effective Waste Management Practices Add Value to Prefabrication

While pre-fabrication can help minimize waste, proper waste management is also crucial. Waste management is the care of trash and remaining material. And if builders are using expandable prefab goods, they should make a plan for dealing with any waste that may still occur. Keyi thinks that if prefabrication is paired with smart waste management, construction would be better. For instance, construction teams could deploy bins to divide out different kinds of waste. They can have one bin for wood, another for metal and a third for plastic. That makes them easier to recycle, rather than throwing them out.

There is also the aspect of training workers on treating materials with care as an essential component of waste management. The more everyone knows how to avoid mistakes, the less waste there will be in the first place. By inspiring laborers to see how they can use materials wisely, construction sites might be cleaner and more efficient. See when builders use prefabricated products by Keyi they start with less wastage anyway. But with smart waste management, they can take these improvements even further. Another helpful habit is tracking how much waste they have. Builders also can see what kinds of waste they are producing and work to reduce it in the future.

In the end, prefabrication is an awesome means of reducing construction waste. When it is followed by effective waste management, the gains even become more great. Keyi is committed to helping builders build better with less waste and people can get a cleaner and healthier living environment.

Table of Contents

- How Prefabrication Can Reduce Construction Waste on Wholesale Projects

- Adopting Sustainable Construction Practices - What to Look for In Prefab Solutions

- The Best Places to Shop for Quality Prefabricated Products That Reduce Waste

- How Prefabricated Elements Can Trim Construction Site Waste

- How Effective Waste Management Practices Add Value to Prefabrication