Customized folding container house

Place of Origin: |

Suzhou, Jiangsu |

Brand Name: |

Folding container room |

Model Number: |

KYCE2024-A2 |

Certification: |

CE |

Minimum Order Quantity: |

7 sets |

Delivery Time: |

7 days |

Supply Ability: |

Can produce 200 per day |

- Description

- Product Overview

- Competitive Advantage

- Recommended Products

Description

Alternative names: Container houses, rapidly - assembled container houses, container rooms, container mobile houses, integrated houses.

Applications: Offices, residences, homestays, warehouses, temporary accommodation for construction sites, warehouses, temporary shelters after disasters, etc.

|

Item |

Details |

|

External Dimensions (mm) |

5800 L * 2500 W * 2380 H MM |

|

Folded Dimensions (mm) |

5800 * 2480 * 570 |

|

Total Mass (kg) |

1000 - 1300 (including doors, windows and simple indoor electrical switches and sockets. 8 sets can be accommodated in 1 * 40HQ) |

|

Main Frame - Top Main Beam |

Rectangular square tube 60 × 80 × 1.3 mm |

|

Main Frame - Top Bearing Bottom |

Rectangular square tube 40 × 1.3 mm |

|

Interior Ceiling |

Color - steel facing v930 * 0.25 mm |

|

Insulated Glass Wool |

Glass wool roll 50 mm (unit weight 16 kg) |

|

External Roof Panel |

Galvanized sheet 0.5 mm |

|

Overall Frame Protective Coating |

Electrostatic spraying / high - gloss |

|

Lifting Head |

155*110 * (6 mm) |

|

Bottom Frame - Bottom Main Beam |

Rectangular square tube 60 × 140 × 1.3 mm |

|

Bottom Frame - Bottom Bearing |

Rectangular square tube 40 × 1.3 mm |

|

Bottom Frame - Front and Rear Main Beams |

Rectangular square tube 60 × 80 × 1.3 mm |

|

Upright - Side Wall Frame |

Rectangular square tube 40 × 60 × 1.3 mm |

|

Galvanized Belt Buckle Groove |

50 mm |

|

Folding Hinge |

Galvanized hinge 13 mm |

|

Floor |

Fire - proof glass - magnesium floor 18 mm |

|

High - end Steel Door |

High - quality safety door (warm white) 970 mm * 1970 mm |

|

Anti - theft Window |

930*1120, plastic - steel anti - theft integrated window, glass thickness 4mm (warm white) 2PCs |

|

Simple Power Distribution |

Electrical wiring is installed strictly in accordance with explosion - proof specifications. All electrical products shall comply with ce certification. Connect the circuit according to the electrical engineering specification. Indoor: coil in4² national standard flexible copper wire, 20 Acircuit circuit breakers 1, socket input wire 2.5², single three - hole socket 1pc, single five - hole sockets 3, 2 lights |

|

Wall Panel |

50 - mm composite panel 0.23 mm + basalt rock wool (unit weight 50 kg) + 0.23 mm |

|

Optional Accessories |

Furniture, sanitary facilities, kitchens, air conditioners, accommodation appliances, offices, dormitories, toilets, bathrooms, shower rooms, steel roofs, assembled panels, decorative materials, etc. |

|

Load - bearing / Horizontal - Roof Load - bearing Capacity |

≥ 50 kg/m² |

|

Load - bearing / Horizontal - Aisle Load - bearing Capacity |

≥ 200 kg/m² |

|

Load - bearing / Horizontal - Floor Load - bearing |

≥ 150 kg/m² |

|

Load - bearing / Horizontal - Wall Side Pressure |

≥ 80 kg/m² |

|

Load - bearing / Horizontal - Wall Deformation Coefficient |

300 kg/m² |

|

Fire Rating |

Class A |

|

Earthquake Rating |

Level 10 |

|

Wind Resistance Rating |

Level 10 |

|

Customization Note |

All the above specifications can be customized according to requirements |

All the above specifications can be customized according to requirements.

Product Overview

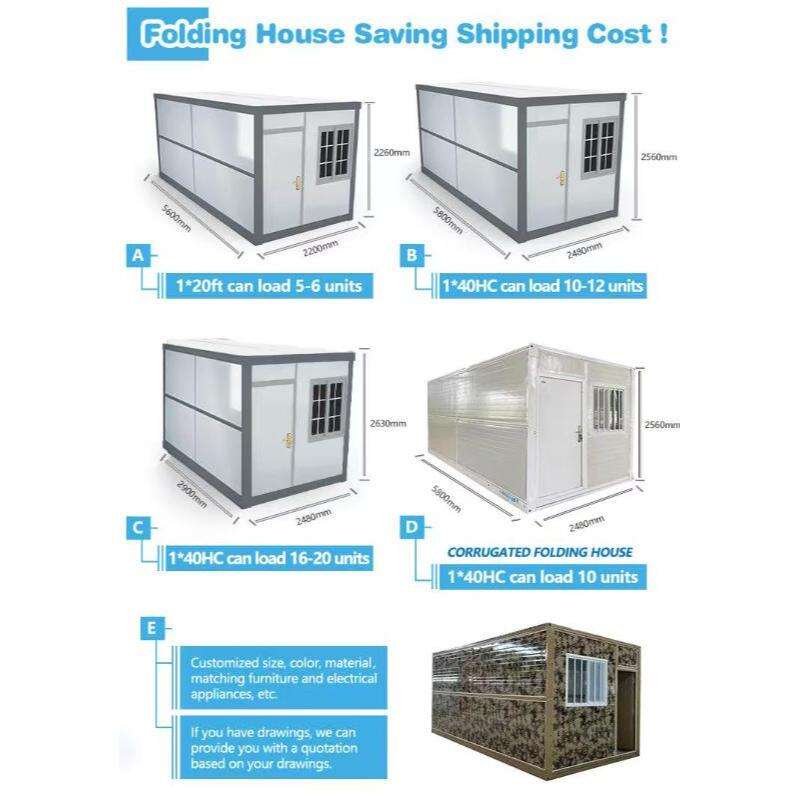

This folding container house is designed with the core concepts of "high strength, rapid deployment, and all - scenario application". It is specifically tailored for scenarios such as construction site camps, emergency resettlement, and business expansion. Utilizing a military - grade galvanized steel structure frame and modular folding technology, its thickness is only 570mm after folding. A single 40HQ container can load 14 sets, reducing transportation costs by 65%. On - site assembly can be completed within 1 - 2 hours. With Class A fire - proof rock wool wall panels and seismic and wind - resistance performance of level 10, it meets safety requirements in extreme environments and is an ideal choice for temporary and semi - permanent buildings.

Core Parameters and Performance Highlights

1. Exceptional Structural Load - Bearing Capacity

Frame System: The main beam uses a 60×140×1. 3mm rectangular galvanized square tube, the uprights adopt 40×60×1. 3mm thickened steel structures, and key nodes are equipped with 6mm galvanized hinges. The entire frame undergoes electrostatic spraying for anti - rust treatment. It can withstand wind at level 10 and earthquakes at level 10, with a service life of over 15 years.

Load - Bearing Capacity: The roof load - bearing capacity is ≥50kg/m², the floor load - bearing capacity is ≥150kg/m², and the aisle load - bearing capacity reaches 200kg/m², supporting equipment storage and high - density human activities.

2. Ultimate Space Efficiency

Unfolded Dimensions: 5800×2500×2380mm (length × width × height), providing a practical area of 14. 5㎡.

Folded Volume: 5800×2480×570mm, with a single - set weight of 1000 - 1300kg, leading the industry in transportation and warehousing efficiency.

3. Safe and Environmentally - Friendly Configuration

Fire - Proof Wall: 50mm sandwich composite panel (0. 23mm color - steel plate + 50kg/m³ basalt rock wool + 0. 23mm galvanized plate), with Class A fire - proof certification and sound insulation of over 30dB.

Anti - theft Doors and Windows: Standard - equipped with a warm - white safety steel door (970×1970mm) and double - layer plastic - steel anti - theft windows (930×1120mm, 4mm tempered glass), featuring anti - prying and anti - explosion designs.

Electrical System: CE - certified moisture - proof wiring, with a 4² national standard copper wire main line + 2. 5² branch line, equipped with a 20A circuit breaker, 4 five - hole sockets, and LED lighting, ready for plug - and - play.

4. Scene - based Functional Expansion

Floor Upgrade: The standard - equipped 18mm fire - proof glass - magnesium board, with optional PVC anti - slip or wood - grain finishes.

Accessory Adaptation: Supports pre - reserved air - conditioning holes and pre - embedded plumbing pipes for bathrooms, and can be expanded into multi - functional spaces such as kitchens, shower rooms, and offices.

Industry - Leading Process Details

Top Structure: 60×80×1. 3mm rectangular main beam + 0. 5mm galvanized roof panel, paired with a 50mm glass wool insulation layer (16kg/m³), achieving warmth in winter and coolness in summer. Bottom Reinforcement: 60×140×1. 3mm main beam + 40×1. 3mm load - bearing cross - beam, adaptable to complex foundations such as gravel and muddy ground.

Quick Hoisting: Standard - equipped with 155×110×6mm galvanized lifting heads, supporting multi - mode handling by forklifts and cranes.

Six Application Scenarios

1. Construction Site Camps: Workers' dormitories and project departments can be set up within 2 hours to meet living needs during the construction period.

2. Post - disaster Emergency: With Class A fire - proof rock wool walls and a level 10 seismic - resistant frame, a safe resettlement point can be formed within 48 hours.

3. Commercial Spaces: The exterior facade can be customized with corporate VI colors and transformed into convenience stores, cafes, or exhibition halls.

4. Homestays and Travel Lodgings: Paired with bathroom and kitchen modules, it can create low - cost mobile vacation homes.

5. Equipment Warehousing: The 150kg/m² load - bearing floor is suitable for tool storage and small - scale production lines.

6. Medical and Educational Facilities: Modular splicing can form temporary clinics and classrooms to serve remote areas.

Customization Services and Global Delivery

Supports all - round customization of dimensions, layouts, and interiors:

Material Upgrade: All materials can be comprehensively upgraded. Function Upgrade: Optional integrated bathrooms, photovoltaic power supply systems, or intelligent access control.

Global Certification: Complies with EN1090 EU steel structure standards and ISO9001 quality systems, and is exported to regions such as Southeast Asia, the Middle East, and Africa.

Competitive Advantage

1.Enhanced transportation efficiency, cost savings of up to 60%

2.Military - grade structural strength, extending service life by 50%

3.Extremely rapid deployment. Installation can be completed in 1 hour and it's ready for use immediately. Just connect water and electricity and fix the foundation (a foundation - free design is optional). A single person can complete the construction of a single container in 2 hours. Compared with traditional container houses (which require hoisting and welding and take 1 - 2 days), the efficiency is increased by 10 times, meeting the 48 - hour emergency response requirement after disasters.

4.Full - scenario adaptability, stable use from - 30℃ to 50℃. The standard - equipped wall is a 50mm rock wool sandwich panel (thermal conductivity 0.043W/m·K), which can be upgraded to a 75mm sandwich structure, paired with insulating glass windows (heat transfer coefficient ≤ 2.0W/㎡·K). It achieves heat preservation in cold regions and heat insulation in high - temperature regions, with the indoor - outdoor temperature difference controlled at over 15℃, meeting basic comfort needs without additional energy consumption.

5.Low - carbon and environmentally friendly, 100% recyclable. The material utilization rate reaches 95%. Scrap steel can be 100% recycled, and the recovery rate of rock wool boards exceeds 80%. Construction waste is reduced by 70% compared with traditional color - steel houses. The water - based paint spraying process is adopted during production, reducing carbon emissions by 40%, and meeting global green building certification standards (such as LEED, BREEAM).

6.One - stop service, reducing full - cycle costs by 40%. Provide full - chain services from design, production, transportation to installation, supporting "turn - key projects":

Cost transparency: The unit price of standardized modules is 30% lower than that of customized containers, and there are no hidden construction costs.

Convenient maintenance: The modular design of components allows for local replacement in case of damage, reducing maintenance costs by 90%.

Global response: Support 40 - foot container sea freight and provide fast delivery in regions such as Southeast Asia, the Middle East, and Africa.

7. Compliance certification, controllable risks. Passed ISO9001 quality management system, EN1090 EU steel structure certification, and China's Class A fire - proof standard, and provides a third - party load - bearing inspection report (load - bearing capacity ≥ 300kg/㎡), avoiding risks in construction site safety inspections, and is suitable for government projects and international projects with strict compliance requirements.